COURSES

Investmech offers training opportunities for engineers. The courses are attended by self-

Round table technical sessions

Not more than 10 attendees get together for interaction sessions to do the following:

- Guided self-

study of material - Investmech demonstrates application of the material in projects

- Solving of problems to demonstrate use of the material

- Solve problems submitted to Investmech before the session

Investmech supplies all relevant documentation (standard(s), books, notes, etc.).

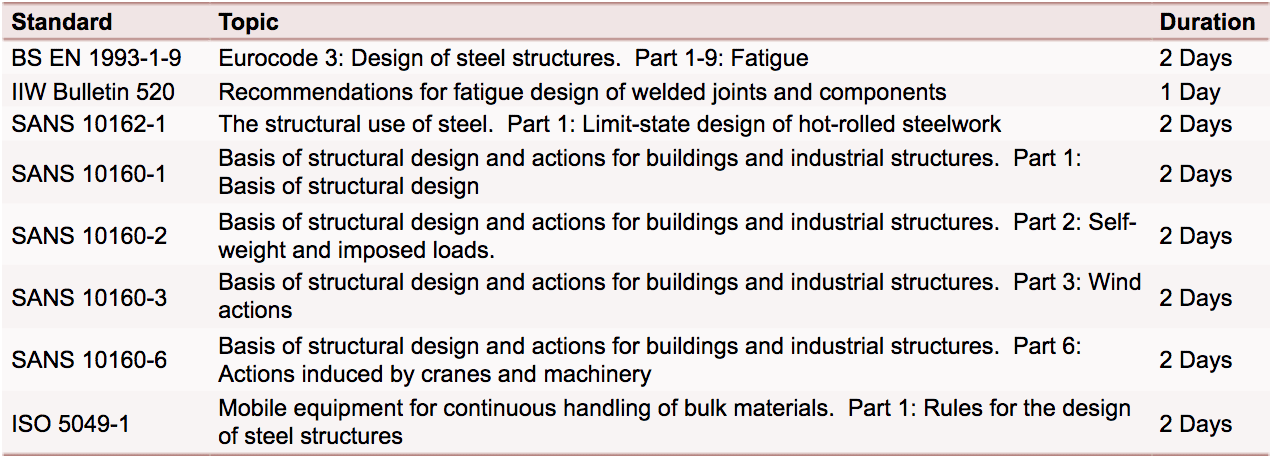

The topics included are presented at present (please contact us for a schedule, venue and cost):

Round table technical presentations

The topics below, which are only a few, are presented in a round-

In-

Investmech offers its clients the opportunity to send personnel to work with our engineers on the client’s projects and in such way realise technology transfer to the client engineer. In some cases the client engineer does most of the work under the guidance of Investmech experts. This hands-

Guided off-

Investmech developed this training opportunity for engineers who does not have the availability to attend presentations or training sessions. This opportunity works as follows:

- Course members works from any convenient place where there is e-

mail and Internet. - Course members can start at any time.

- Course members work at their own pace.

- Study material is loaded onto Investmech’s cloud server for download by course members. This include presentations, videos, standards, published media, etc.

- Real life problems relevant to the course members are used as case studies.

- Effective digital communication platforms are used to guide problem solving and facilitate consulting.

Please contact us for more information.

COURSE DETAIL

Below is more detail of courses. Note that not all Investmech courses are listed below.

ADVANCED BOLTS, NUTS & WASHERS COURSE

- Objective

To obtain advanced knowledge in the design and analysis of bolted joints, bolts, nuts and washers subject to static and transient loads.

Critical Learning Outcomes

After completion of this course the attendee will be able to:

- Bolt manufacturing techniques

- Designate bolts, nuts and washers according to SANS 1700

- Design bolted connections according to SANS 10162-

1 - Compile installation instructions

- Describe the mechanisms leading to bolt failure

- Perform bolt fatigue calculations

- Calculate required bolt torque

- Specify lubrications for bolted connections

- Algoa curves and their use

- Apply knowledge on bolt failures from practice

- Model ductile and brittle fracture of bolts

- Understand environmental affects on bolt integrity

- Select materials and heat treatment thereof for self-

made bolts and nuts - Finite element modelling of bolts and bolted joints

Documents issued with the course

Investmech will provide each attendee with an iPad Mini with course notes and legal copies of standards and documents loaded.

Theme 1. Designation of bolts, nuts & washers

Theme outcomes:

- Explain difference between Grade and Class designation of bolts & nuts

- Describe the parameters used in the designation of bolts, nuts & washers

- List designation formats

Theme topics:

- Grade classification of Bolts & Nuts

- Class classification of Bolts & Nuts

- Discussion of SANS 1700 requirements

- Mechanical properties of bolts:

- Tensile strength

- Yield strength

- Elongation

- Poisson ratio

- Engineering and true stress-

strain constitutive models for bolt materials - Bolts & nuts to use on: cranes, bridges, high temperature guilotines, harsh environments, building structures, etc. (as required by standards, regulations, safety, hazards, etc.)

Theme 2. Static design of bolted connections to SANS 10162-

1 & DIN 18800 Theme outcomes:

- Calculate the tensile & shear resistance of bolts

- Calculate the bearing and other resistance of parent metals

- Size bolt groups in splices, etc.

- Specify bolt designations for use in bearing-

type and friction- grip connections

Theme topics:

- Preferred sizes of bolts

- Friction grip and bearing-

type connections - Uses of high-

strength friction grip bolts - Shear resistance

- Tensile resistance

- Bolts in shear & tension

- Slip resistance

- Connections in slip & tension

- Bolt pretension

- Bolt design examples

- Prying

- Bearing resistance

- Connection design examples

- Designation of bolts in bearing-

type joints - Designation of bolts in friction-

grip joints

Theme 3. Thread geometry and kinematics

Theme outcomes:

After completion of this theme you will be able to:

- Explain the practical implication of single & multi-

entry threads - Calculate thread geometry

- Designate threads

- Calculate friction effects

- Calculate lifting & lowering force

- Calculate clamping force

Theme topics:

- Single & multi-

entry threads - Thread trignometry

- Thread geometry

- Thread designation

- Friction

- Lifting & lowering forces

- Clamping force

- Examples

Theme 4. Bolt fatigue design

Theme outcomes:

- Calculate the cyclic load on a pretensioned and loose bolt

- Construct the Sr–

N curve for bolts - Describe the effect of pretension on the fatigue life of bolts

- Quantify the effect of free Hydrogen on fatigue life

- Calculate the effect of welds on bolt fatigue life

- Finite element modelling of bolted joints and bolts

- Selection of bolts for variable amplitude loading of joints

Theme topics:

- Bolt fracture surfaces

- Bolt Sr–

N curves - Prying and cyclic loads

- Contact face opening

- Hydrogen embrittlement

- Fatigue calculations

- Fracture Mechanics –

introduction - Case studies

Literature issued with the course

The following will be given to each attendee on an iPad Mini:

SANS 10162-

1. The structural use of steel. Part 1: Limit- state design of hot- rolled steelwork. Standards South Africa. Available at: https://www.sabs.co.za/Standardss/index.asp

FATIGUE AT INVESTMECH

Visit our website for fatigue and fracture mechanics for more information

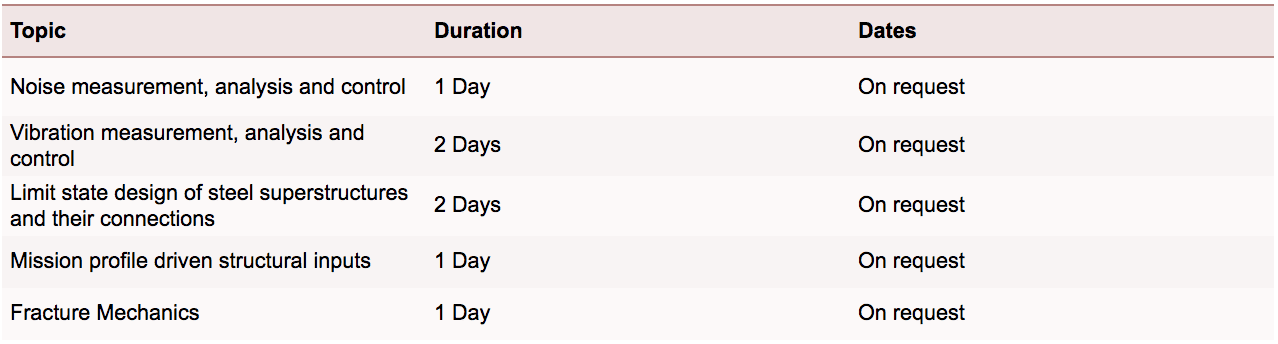

SILOS, HOPPERS & CONTAINERS

Course outline for the design, maintenance and asset integrity management of Silos, Hoppers & Containers

Condition-Based Maintenance CBM

The sole purpose of this web page is to communicate information with Universities and students of those Universities with regards to modules in condition-

GO TO PAGE

Finite element analysis

Mechanical Engineering

Structural Integrity

Root cause analysis

Transient analysis of structures

Structural Inspections

Ventilation

Modelling and Simulation

Machine and Structural design

Noise and Vibration

Pipes, line pipes, etc.

Testing

Industrial Engineering

Courses