Root cause analysis

At Investmech, we carry out cause and effect analysis to find the root cause for failures. The following is a list of typical services offered in this regard:

- Gear failures

- Bearing failures

- Oil degrading

- Shaft failure

- Axle failures

- Structural collapse

- Weld and bolt failure

- Accident reconstruction

- Engine and machine failure

Previous Work

Tempered martensite shaft and axle failure

An inhomogeneous microstructure in a tempered martensite shaft resulted in a “metallurgical” stress concentration resulting in crack initiation far away from a stress concentration. The appearance of coarse lath martensite (280 HV to 290 HV) and plate martensite (350 HV to 352 HV) resulted in a new homogenisation process solution.

Investmech find this the root cause for failure on several components which are made from steel with a 100% tempered martensite microstructure.

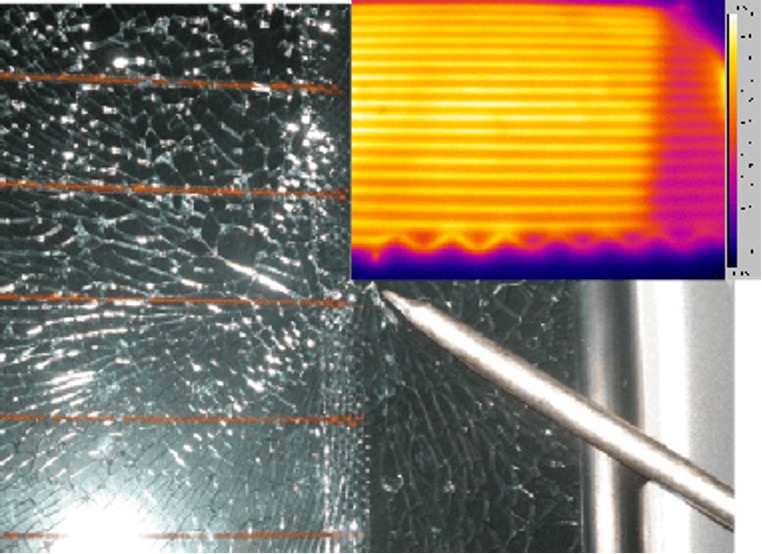

Spontaneuos fracture of hatchback window glass

In this project the root cause for rear window failures were identified. In this assessment residual stress in the glass was measured and the heat treatment changed to increase the strength of the window. Sulphide inclusions were found.

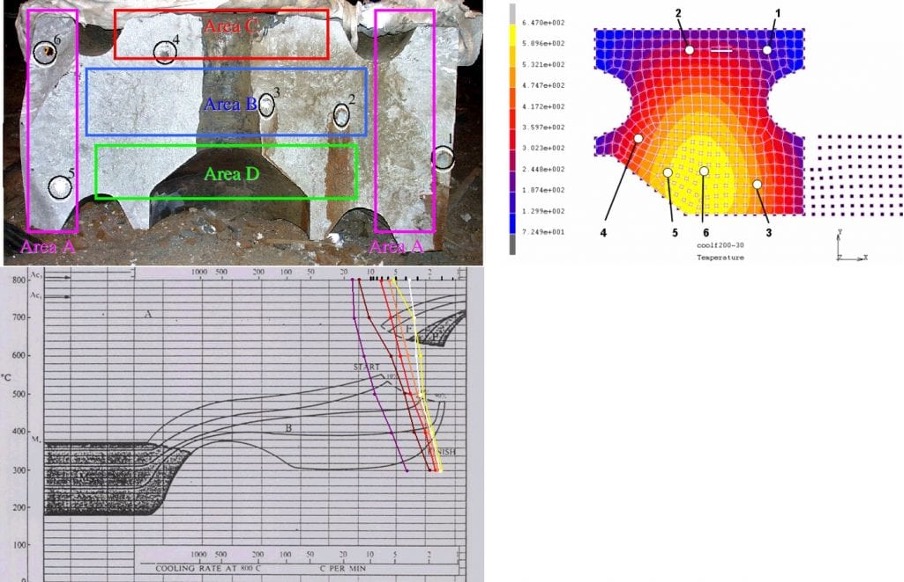

Phase transformation and residual microstructure dependant stress distribution in casts

Cooling rates on casts was solved by changing the cast geometry as well as the cooling rate. A finite element analysis based investigation was carried out to model the time dependent temperature distribution, from which the time dependent phase transformation was calculated resulting in a final residual microstructure distribution. Ignoring phase transformation creep and plasticity Investmech calculated the residual mechanical property and stress distribution that aligned with the catastrophic self-destruction of the cast. Using this verified model solution scenarios were modelled and a final solution implemented.

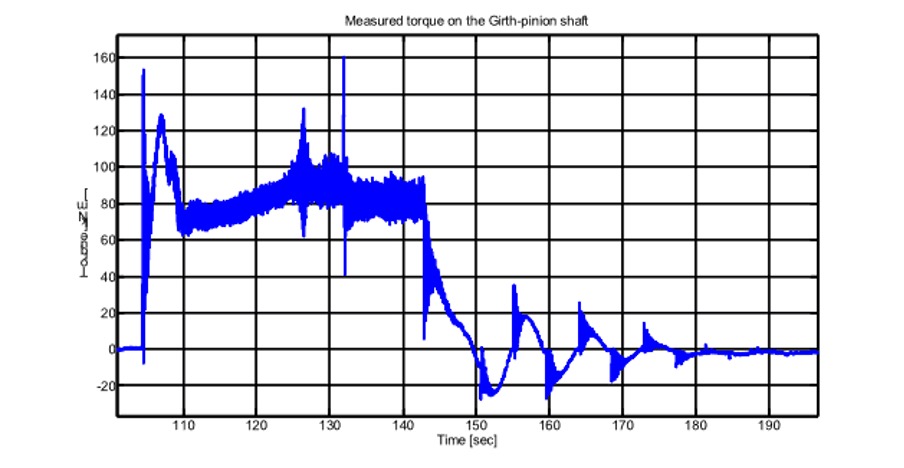

Mill gearbox and drive train failures

Measured torque on mill drives are used to quantify mission profile driven loads to ensure gearbox designs that complies with AGMA and DIN standards. In root-cause investigations Investmech typically uses the following tools and skills:

- Vibration measurement and analysis

- Temperature measurement and analysis

- Oil analysis – chemical composition and ISO cleanliness

Work With Us

If you want to work with us or have any questions, please feel free to get in touch using any of the methods listed below. We will get back to you as soon as possible.

Phone Number

+27 12 664-7604

Address

8 Topaz Ave, Lyttleton Manor, Centurion, 0157

info@investmech.com