Testing

Structural testing

Investmech is equipped with servo-hydraulic and other test equipment that enables us to serve all structural and fatigue test requirements. At Investmech, we offer a niche service in accelerated durability testing. We use ARX models to calculate structural inputs that reconstruct recorded or specified responses. This algorithm is used to calculate drive signals for servo-hydraulic test rigs to excite a dynamic structure reconstructing recorded responses.

Typical tests Investmech carries out on a continuous basis:

- Four to six poster durability tests on vehicles, trailers, trucks.

- Durability tests on components.

- Roll-over and falling-object protective structures – ROPS and FOPS testing

- Shaft steelwork accelerated durability testing.

- Low temperature brittleness tests.

- Exhaust pipe vibration and thermal fatigue testing

- Full-scale fatigue tests on components and structures

- State-of-the-art multi-axial service load and service response reconstruction

- Road simulator vehicle qualification

- Static testing

- Experimental design verification

- Dynamic characterization testing

- Seat belt anchorage point

- Towing device durability testing

- Damper characterization and durability testing

- Vibration testing of electronic and mechanical equipment – seismic testing

Typical structural testing services we offer

Durability testing

- Accelerated durability testing

- Four-poster tests

- Component testing

- Roll-over Protective Structure (ROPS) & Falling Object Protective Structure (FOPS) tests

- Low temperature brittleness tests

- Characterization

- Material testing

- Fatigue curves

- COD and J-integral crack propagation

- Fracture toughness

Accelerated durability testing

Accelerated durability testing is a technology where time domain response reconstruction of field measured responses is carried out, and, with the aid of mission profiles and fatigue analysis an accelerated test performed. This enables Investmech to carry out a 200,000 km durability test on a motor vehicle in approximately 22 days. This result in cost benefits and significant reduction of the safety risks of carrying out such a test.

The technology used in the accelerated durability test is the reconstruction of field recorded strain and acceleration signals on a dynamic test rig, consisting of servo-hydraulic actuators.

Characterization testing

Investmech applies internationally accepted algorithms to characterise suspension units and polymers in terms of their damping and stiffness properties.

Material Testing

Due to Investmech’s experience in the field of metal fatigue and fracture mechanics, Investmech carries out tests to quantify the fracture toughness and S-N properties of materials.

Conformance testing

At Investmech, we carry out several conformance tests in the laboratory. The tests are carried out according to user specified or international requirements.

- ROPS and FOPS

- Towing devices

- Exhaust pipes

- Seismic resistant parts for the nuclear industry

- Vehicle rims

- Cranes and super structures

- Other tests according to customer requirements and international standards.

Examples of structural testing projects

Exhaust thermal fatigue testing

Exhaust thermal fatigue testing is done using a heat source capable of heating to 800 °C for a 4,000 cc engine full throttle flow rate.

ROPS and FOPS testing

ROPS and FOPS testing are done using standard prescribed falling objects and quasi-static test equipment

Multi-poster accelerated durability testing

Investmech offers accelerated durability testing on vehicles, structures, components, seismic instrumentation, etc. where recorded strain and acceleration responses are reconstructed in the time domain by calculating drive signals for multi-axial servo-hydraulic actuators.

Test severity ratings of between 10 and 14 are used on most tests. In exceptional cases test severity ratings of 20 to 25 are used. However, in these extreme test cases system dynamics may influence the accuracy of the durability test.

Testing of shaft steelwork

Investmech carries out several quasi-static and variable amplitude tests on shaft steelwork to ensure the integrity of joints and members.

Characterization of seismic bearings

Investmech performs characteristic, strength and fatigue tests on seismic bearings for the nuclear industry.

Instrumentation and measurement

Investmech has vast experience in the instrumentation and measurement of strain, acceleration, force, temperature, flow, pressure, current and voltage. Recorded signals are used on a continual basis in the verification of structural integrity, or the solving of engineering problems. The Investmech team use state-of-the-art recording equipment and transducers. Here are some examples of simple and complex measurements carried out by Investmech:

- Acceleration and strain measurements for time domain reconstruction of inputs on vehicles, load boxes, trucks, ships, aeroplanes, oil rigs, reactors, steam boilers, furnaces, large super structures, etc.

- Noise, vibration, and harshness (NVH) measurements and control on automotive & military vehicles, plants, structures, etc.

- Acceleration measurements on man cages in mines, vehicles, railway vehicles, to quantify whole body response.

- Strain, acceleration and temperature measurements on high temperature pressure vessels, ladles, refractory, furnaces, steam pipes, etc.

- Strain and acceleration measurements and control on pipes.

- Acceleration measurements on offshore oil rigs, aeroplanes, railway vehicles, etc.

- Modal analysis and operational mode extraction (Synthol reactors, ships, pressure vessels, automotive vehicles, cellular masts, trucks, electric motors, crushers, electrode control systems, furnaces, steam and other piping, etc).

Remote data logging and analysis using cloud servers and mobile networks enable Investmech to do online monitoring of a vast range of equipment and structures.

These were applied on mills, gearboxes, automotive vehicles, ladles, furnaces, pipes, shaft steelwork, mining conveyances, buildings, draglines, vehicles, ships, railway vehicles, trains, towers and masts, bridges, plant super structures, seismic equipment, agitators, nuclear reactors, power stations, etc.

Examples of instrumentation and measurement projects

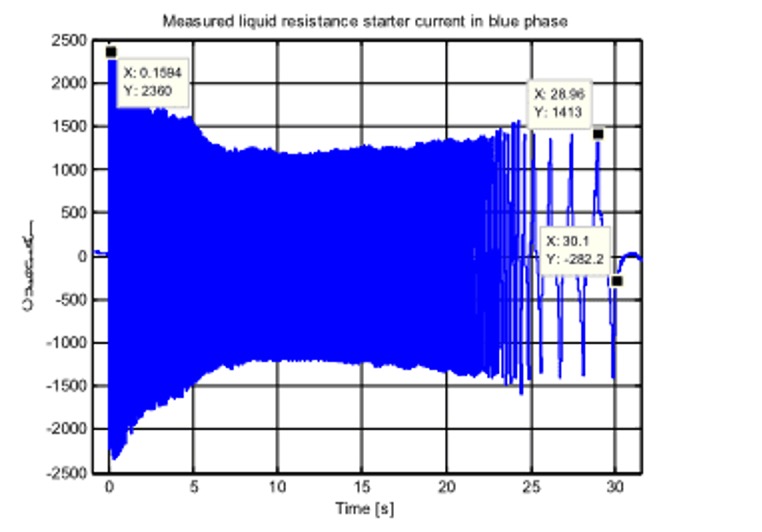

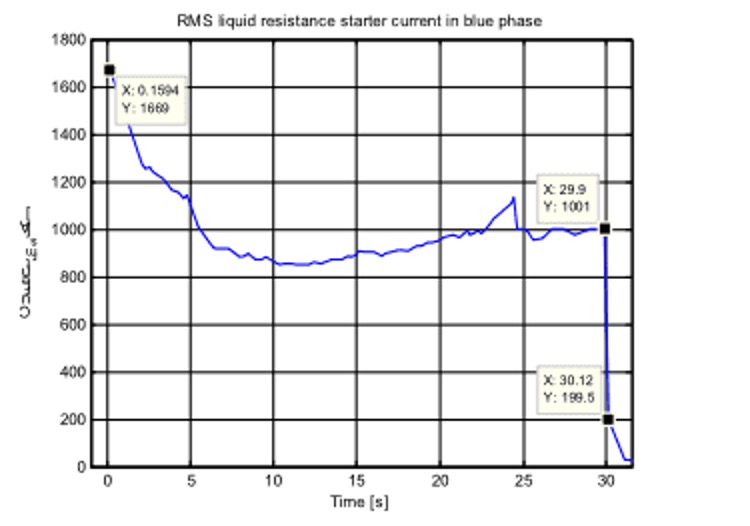

Liquid resistance starter current

The two graphs below are the instantaneous and root mean square current measured in a conductor of a liquid resistance starter for an electric motor of a ball mill. These currents are used to confirm the condition of the liquid in the liquid resistance starter and to do root cause assessment if there are problems.

Infrared thermography

This is used as a powerful tool in root-cause assessments and condition monitoring.

Work With Us

If you want to work with us or have any questions, please feel free to get in touch using any of the methods listed below. We will get back to you as soon as possible.

Phone Number

+27 12 664-7604

Address

8 Topaz Ave, Lyttleton Manor, Centurion, 0157

info@investmech.com